Ncha laser na pickling bụ ụzọ abụọ dị iche iche maka ịgwọ elu igwe.Nchacha laser bụ usoro ọgwụgwọ elu igwe nke na-eji ọkụ laser na-emepụta site na generator laser na-emepụta ike dị elu iji wepụ nchara, agbapụ agba, na iwepụ ihe mkpuchi.Pickling bụ usoro ọgwụgwọ a na-eji ewepụ nchara, ntụpọ, adịghị ọcha, ma ọ bụ ihe mmetọ n'elu ọla.

pickling

A na-eji mpempe akwụkwọ na-ekpo ọkụ na-ekpo ọkụ mee mpempe akwụkwọ ahụ dị elu dị ka akụrụngwa, a na-ewepụkwa oyi akwa oxide site na nkeji pickling, dozie ma mechaa.Ngwaahịa etiti dị n'etiti efere, na ntọala nke ịhụ na ịdịmma elu yana ihe achọrọ, na-enyere ndị ọrụ aka ibelata ọnụ ahịa ịzụrụ nke ọma.

Uru nke mpempe akwụkwọ pickling

1. Ọdịdị elu dị mma, n'ihi na a na-ewepụ ọnụ ọgụgụ ígwè oxide n'elu site na efere pickling na-ekpo ọkụ, nke na-eme ka ọdịdị elu nke ígwè ahụ dịkwuo mma ma na-eme ka ịgbado ọkụ, mmanụ na eserese.

2. Ogologo akụkụ dị elu, mgbe ọ gbasasịrị, enwere ike ịgbanwe ọdịdị efere ahụ ruo n'ókè ụfọdụ, si otú ahụ belata nkwụsị nke enweghị isi.

3. Mma elu imecha na enhances ọdịdị.

Ngwa

Enwere ike ịsị na mpempe akwụkwọ pickling bụ ngwaahịa na-efu ọnụ n'etiti mpempe akwụkwọ oyi na mpempe akwụkwọ na-ekpo ọkụ.Ọ nwere ọtụtụ ngwa dị iche iche na ụlọ ọrụ ụgbọ ala, ụlọ ọrụ igwe, ngwa ụlọ ọrụ ọkụ ọkụ na akụkụ stamping nke ụdị dị iche iche, dị ka beams, sub-beams, rim, spokes, panel carriage, fan, mmanụ mmanụ kemịkal, ọkpọkọ welded, eletriki. kọbọd, ngere, ubube ígwè, wdg, nwere atụmanya ahịa sara mbara.N'okpuru ebe a, anyị ga-ewebata usoro teknụzụ nke usoro pickling.

Ụkpụrụ pickling

Pickling bụ usoro elu nke na-eji ngwọta acid wepụ ihe nchara na nchara n'elu ígwè, na-ejikọta ya na tupu emee ihe nkiri.N'ozuzu, workpiece na-emikpu na a chemical ngwọta dị ka sulfuric acid wepụ oxides na ihe nkiri ndị ọzọ na metal elu, nke bụ tupu ọgwụgwọ ma ọ bụ n'etiti ọgwụgwọ nke electroplating, enamel, Rolling na ndị ọzọ Filiks.A makwaara dị ka nhicha mmiri.

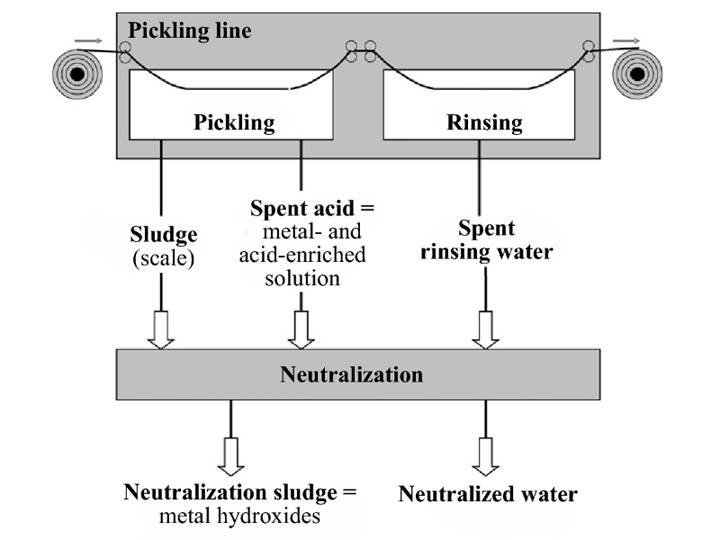

Usoro pickling na-agụnyekarị usoro ịkụnye mmiri, usoro ịgba mmiri na usoro iwepụ nchara nchara.

Asịd ndị e ji eme ihe na-abụkarị sulfuric acid, hydrochloric acid, phosphoric acid, nitric acid, chromic acid, hydrofluoric acid na agwakọta acids.

Usoro Usoro

Ịkọba na akụkụ ígwè → chemical degenreasing (conventional alkaline chemical degenreasing or surfactant degenreasing) → mmiri ọkụ na-asachapụ → mmiri na-ekpo ọkụ → nzọụkwụ mbụ nke pickling → Ịsacha mmiri mmiri → Nzọụkwụ nke abụọ → ịsacha mmiri na-agba ọsọ → nyefee na usoro ọzọ (dị otú ahụ). dị ka: agba kemịkalụ → imegharị ihe → ịsacha mmiri na-agba ọsọ → ọgwụgwọ siri ike → ịsacha → Ọgwụgwọ mmechi → ịsacha → ihicha → Emechara).

Nkwarụ nkịtị

Mbanye ọnụ ọgụgụ iron oxide: Mbanye ọnụ ọgụgụ iron oxide bụ ntụpọ dị n'elu nke emere n'oge ntụgharị ọkụ.Mgbe a kpọchara ya, a na-apịnyekarị ya n'ụdị ntụpọ ojii na ibe, elu ya na-esighi ike, na-enwekarị mmetụta aka, na-apụtakwa ngwa ngwa ma ọ bụ na-akpa ike.Ọ na-emekarị site na usoro ikpo ọkụ na-ezughị okè, usoro nkwụsịtụ na usoro nchịkọta nke pickling.

Ntụpọ ikuku oxygen (esere eserese dị n'elu): na-ezo aka na ntụpọ dị ka ntụpọ, linear ma ọ bụ olulu nke fọdụrụ ka ekpochapụsịrị ọnụ ọgụgụ ígwè oxide dị n'elu ígwè a na-ekpo ọkụ.A na-agbanye mpịakọta ahụ n'ime matriks ahụ, nke a na-eme ka ọ pụta ìhè mgbe ịchachara.Ọ nwere mmetụta ụfọdụ na ọdịdị ahụ, ma ọ dịghị emetụta arụmọrụ.

Macular: ntụpọ edo edo na-apụta na akụkụ ma ọ bụ elu osisi dum, nke a na-apụghị ikpuchi mgbe mmanụ, nke na-emetụta àgwà na ọdịdị nke ngwaahịa ahụ.Isi ihe kpatara ya bụ na arụ ọrụ elu nke warara dị nnọọ na tankị pickling dị elu, mmiri na-ekpo ọkụ adịghị asachapụ eriri ahụ nke ọma, a na-egbochi ọkụ ọkụ na nozzle nke tank ahụ, na akụkụ ndị ahụ adịghị nhata.

N'okpuru-pickling: N'elu nke warara ígwè nwere mpaghara akpịrịkpa ígwè oxide nke na-adịghị ọcha na ezughi oke wepụrụ, na efere elu bụ isi awọ-oji, na azu akpịrịkpa ma ọ bụ kehoraizin mmiri ripples.O nwere ihe jikọrọ ya na usoro acid, tumadi n'ihi na ntinye acid ezughị oke, okpomọkụ adịghị elu, warara na-agba ọsọ ngwa ngwa, na warara enweghị ike ịbanye n'ime acid.

N'ihe karịrị akarị: elu igwe mgbawa ahụ na-abụkarị oji ma ọ bụ oji na-acha aja aja, na-egosi ngọngọ, ntụpọ ojii na-agba agba ma ọ bụ macular, na elu efere ahụ na-adịkarị njọ.Ihe kpatara ya bụ ihe na-abụghị nke underpickling.

Mmetọ gburugburu ebe obibi

Isi ihe na-emerụ emerụ na usoro mmepụta bụ mmiri mkpocha nke usoro ịsa mmiri na-emepụta n'ọkwa niile, uzuzu nke usoro ịgbapụta ájá na-emepụta, alụlụ hydrogen chloride acid nke usoro pickling na-emepụta, na ihe mkpofu nke pickling na-emepụta, na-ekpochasị ihe. phosphating, neutralization na mgbochi nchara.Mmiri mmiri tankị, ihe fọdụrụ n'ihe mkpofu, ihe nzacha ihe mkpofu, akụrụngwa akụrụngwa efu na mkpofu nkwakọ ngwaahịa, wdg. Ihe ndị na-emerụ emerụ bụ hydrogen chloride, pH, SS, COD, BOD?, amonia nitrogen, petroleum, wdg.

Laser nhicha

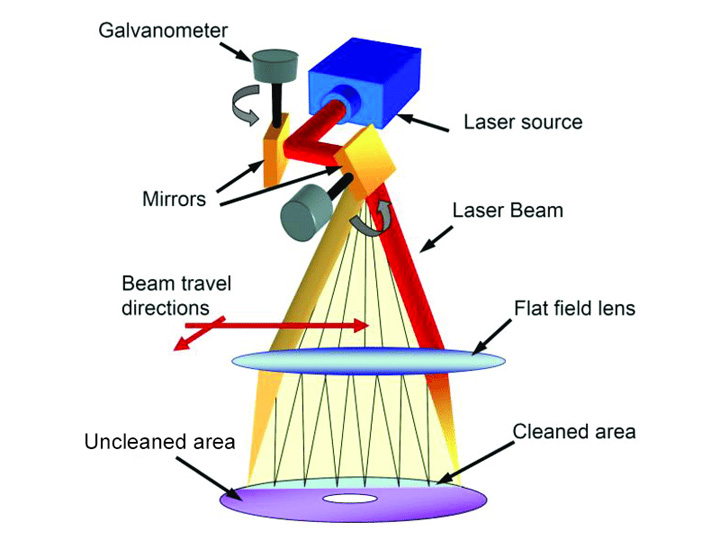

Ụkpụrụ nhicha

Igwe nhicha laserbụ iji ike laser banye n'elu ihe ahụ.Eletrọn dị n'ime ihe ahụ na-amịkọrọ ịma jijiji ike maka ihe dịka 100 femtoseconds, na-emepụta plasma n'elu ihe ahụ.Mgbe 7-10 picoseconds gasịrị, a na-ebufe ike elektrọn na lattice na lattice na-amalite ịma jijiji.Mgbe picosecond gasịrị, ihe ahụ na-amalite ịmepụta nnukwu okpomọkụ, na ihe ndị dị n'ógbè ahụ nke laser na-agbanye ọkụ na-amalite ikpo ọkụ, gbazee na vaporize, iji nweta nzube nke ihicha.

Usoro nhicha & Mmetụta

E jiri ya tụnyere usoro pickling, laser ihicha usoro dị nnọọ mfe, ọ dịghị pretreatment a chọrọ, na ihicha ọrụ nke mwepụ nke mmanụ, oxide oyi akwa mwepụ na nchara na-ewepụ nwere ike rụrụ n'otu oge.Naanị gbanye ngwaọrụ ka ịgbanyụ ọkụ, wee hichaa ya.

Usoro nhicha laser nwere ike iru ọkwa nhicha ụlọ ọrụ kachasị elu nke ọkwa Sa3, ọ fọrọ nke nta ka ọ bụrụ mmebi nke ike, hydrophilicity na hydrophobicity nke elu ihe.Ọ bụ nke ọma karịa pickling.

Uru na ọghọm

Usoro usoro na chọrọ ọrụ chọrọ

E jiri ya tụnyere ngwá ọrụ pickling nwere ihe karịrị usoro iri na abụọ, laser Cleaner enwetala usoro kachasị mfe ma nweta otu nzọụkwụ.Nke ukwuu na-ebelata oge nhicha na ọnwụ ihe.

The pickling usoro nwere nlezianya chọrọ na ọrụ usoro: workpiece ga-kpamkpam degreasing iji hụ na àgwà nke nchara na-ewepụ;A na-achịkwa ntinye nke ngwọta pickling iji gbochie ọrụ ahụ ka ọ ghara imebi ya n'ihi oke acid itinye uche;okpomọkụ na-achịkwa dị ka usoro nkọwapụta iji zere mmebi nke workpiece na The akụrụngwa na-akpata corrosion;tankị na-ekpo ọkụ na-eji nwayọọ nwayọọ na-etinye sludge, nke na-egbochi ọkpọkọ kpo oku na ngwaọrụ ndị ọzọ na-achịkwa, ọ dịkwa mkpa ka a na-ewepụ ya mgbe niile;na mgbakwunye, ọ dị mkpa ịṅa ntị n'oge pickling, nrịbama injection, sputtering ọrụ, iyuzucha akụrụngwa, wdg.

Laser ihicha nwere ike na-aghọta nzuzu-dị ka ọrụ ma ọ bụ ọbụna akpaka unmanned ọrụ mgbe mwube parameters na mmalite ogbo.

Mmetụta nhicha na mmetọ gburugburu ebe obibi

Na mgbakwunye na mmetụta ihicha siri ike, usoro nhicha laser nwekwara uru nke nnabata ka ukwuu.

Oxygen macular, redness na blackening na-emekarị n'ihi mmejọ na-arụ ọrụ nke usoro pickling, na ọnụ ọgụgụ jụrụ ya dị elu.

The mmiri dobe laser nnwale na-egosi na ọ bụrụgodị na laser ihicha bụ supersaturated, ọ ka nwere ike dara luster, na adịghị emepụta hydroxide na ndị ọzọ na-emetọ, nke na-agaghị emetụta na-esote nhazi ụzọ dị ka ịgbado ọkụ.

A gaghị enwe mmetọ gburugburu ebe obibi dị ka mmiri na-ekpofu ihe na slag na usoro dum nke nhicha laser, nke bụ usoro nhicha nke greenest.

Ọnụ ego ntụgharị VS Unit

Ngwá ọrụ pickling na-achọ kemịkalụ ka ihe oriri, yabụ ọnụ ahịa otu ahụ nwere mbelata akụrụngwa + ọnụ ahịa nri.

Igwe na-ehicha laser anaghị achọ ihe eji eme ihe ma ọ bụghị ngwa ịzụrụ ihe.Ọnụ ego otu unit bụ mbelata nke akụrụngwa.

Ya mere, ibu ihicha ọnụ ọgụgụ na ogologo afọ, ala unit na-eri nke laser ihicha.

Ngwakọta nke ahịrị mmepụta pickling chọrọ usoro mgbagwoju anya, na ọnụ ọgụgụ nke ndị na-emepụta ihe maka ihe ndị dị iche iche dị iche iche abụghị otu, ya mere, nchigharị mmepụta ihe na-achọ nnukwu ego ngbanwe, na ihe a ga-ehicha n'ime obere oge. na-alụbeghị di ma ọ bụ na ọ nweghị ike ịgbanwe agbanwe.

Enweghị ego ntụgharị maka nhicha laser: mgbe ịgbanwere paramita sọftụwia nke otu igwe nhicha ahụ, enwere ike nweta mmetụta nke ihicha efere ígwè otu nkeji na alloy aluminum na nkeji ọzọ.Ọ dị mma maka ụlọ ọrụ iji mejuputa mmepụta mgbanwe JIT.

Nchịkọta

Pickling efere nwere nnukwu ngwa na ngwa dị omimi n'ichepụta mmepụta, ma na-arụ ọrụ dị mma na nkwado ụlọ ọrụ mmepụta ihe.Otú ọ dị, site na nkwalite na-aga n'ihu nke ụlọ ọrụ mmepụta ihe, a na-ejikwa nwayọọ nwayọọ na-eme ka njikarịcha ikike na nhazi nhazi.

Site na mmụba nke mmata gburugburu ebe obibi ndị mmadụ, gọọmentị na ụlọ ọrụ nwere nnukwu ihe achọrọ maka ahịrị mmepụta ihe, na oke uru nke ụlọ ọrụ metụtara na-adịwanye njọ.The n'ozuzu gburugburu ebe obibi bụ ihe mma maka laser ihicha.

Ma eleghị anya, n'ime afọ iri na-abịanụ, mpempe akwụkwọ pickling ga-enwe aha ọhụrụ - akwa nhicha laser.